Jetter Features

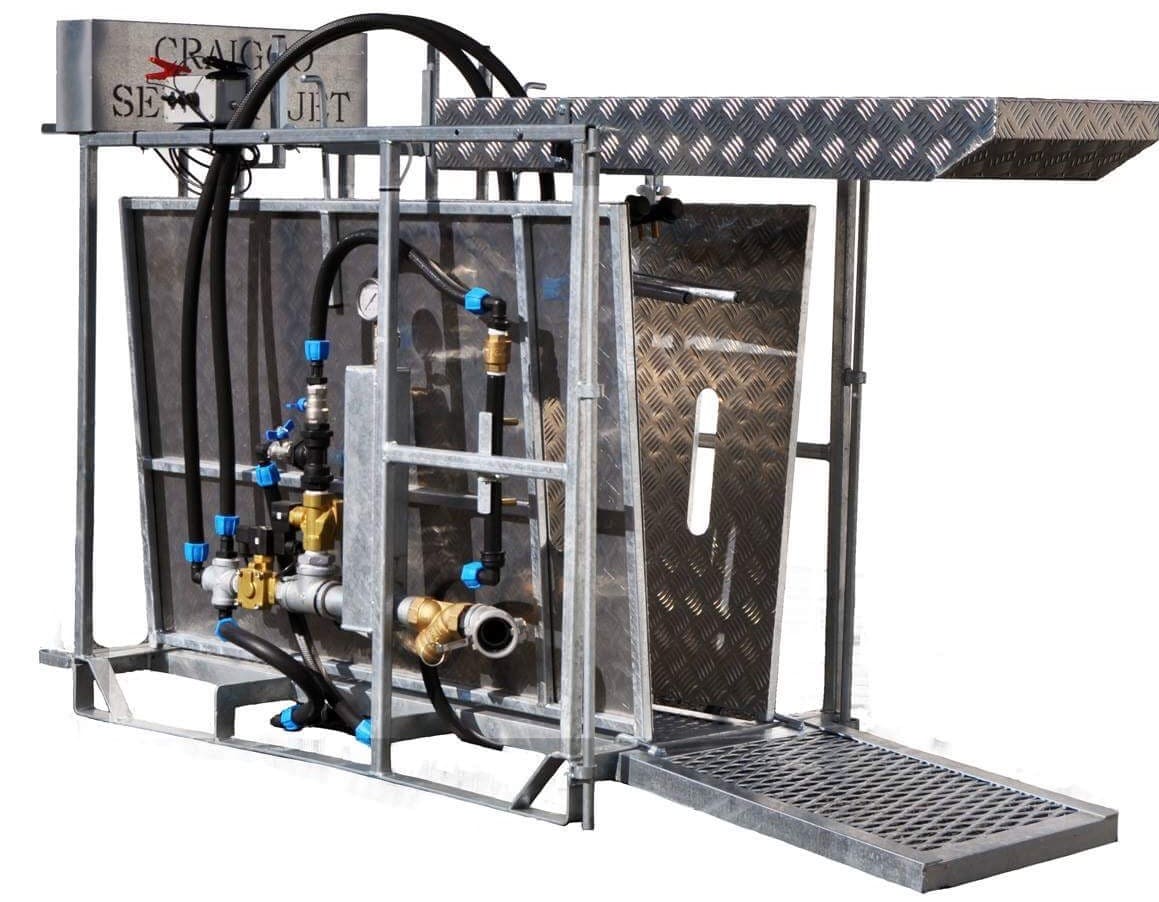

Key Features

- Electronic Sensor or a "magic eye" detects the presence of sheep in the jetter.

- 2 Solenoid Valves allow dose rates of up to 3 litres for ewes. This volume can be reduced by using only 5 jets when treating lambs.

- 6 Spray Bars and 20 Jets positioned to provide optimum penetration and coverage for fly and lice control.

- Frame and Components are hot dipped or electro galvanised to protect against corrosion.

- Some sensors on the market have an in-built relay which is generally the part that may fail. As our relay can be replaced the cost is minimal. A spare relay is supplied.

- Electrical System is protected against short circuits by using a thermal overload which is easily reset. No fuses to replace.

- Exit ramp is supplied with the jetter. Poor drainage under the jetter can cause baulking which the exit ramp helps to minimise.

- Fire Hose and Nozzle is supplied with the hose kit.

- Automatic Gate closes if the system pressure drops below a predetermined pressure.

- Internal Panels are adjustable in both width and spring pressure.

- Jetter weight is less than 100 kg.

Craigco SensorJet

Jetting Principles

Effective jetting is achieved by thorough wetting through to the skin in areas most likely to be affected by Flystrike that is from the poll, over the shoulders, down the back line, over the crutch and around the pizzle. Wetting to the skin maximises the efficacy of the pesticide giving maximum length of protection. The volume of dip chemical retained in the fleece is important in achieving maximum results. The industry recommended dose rate is 0.5 of a litre per month of wool growth, use appropriate spray nozzles so that the important areas are covered. The number of nozzles, operating pressure and the speed of sheep through the jetter determines the volume of dip applied. Jetting should not be a race against the clock. The ideal situation is to have sheep walking through the jetter, not running or barging. Positioning the jetter at an angle to the drafting race will help regulate the flow.

Pump

We supply Davey twin impellor pumps with our jetters. Twin impellor pumps provide high pressure and high flow which are well suited for sheep jetting. Enough pressure at the spray nozzles is required to provide adequate wetting through to the skin. Jetting trials which were carried out in 1992 by the Trangie Agricultural Engineering Research Unit of Australia found that a pump capable of 6 litres per second (360l/min) with a nozzle pressure of 450kPa (65PSI) was required. High nozzle pressures can cause misting and will actually hurt the animal making it reluctant to pass through the jetter in the future. We offer the Davey Twin Impellor pump in a 6.5 or 9 horsepower variant. View the full specifications below.